Better Than Other Blades

About the B-TOEM Blades

Benefits—Features—Design

- Superior blades; retain a sharp cutting edge due to high hardness

- Sturdy in rocky terrains, very resistant and ductile

- PEER bearings

- Heavy duty hub

- Domestic components—Assembled in the USA

- 20% — 40% longer wear— Reduced cost per acre

- Lifetime warranty on breakage

- Greater durability, 30%-40% longer wear-life

- Special high—grade, quality steel

- Unique patented heat-treating processed steel

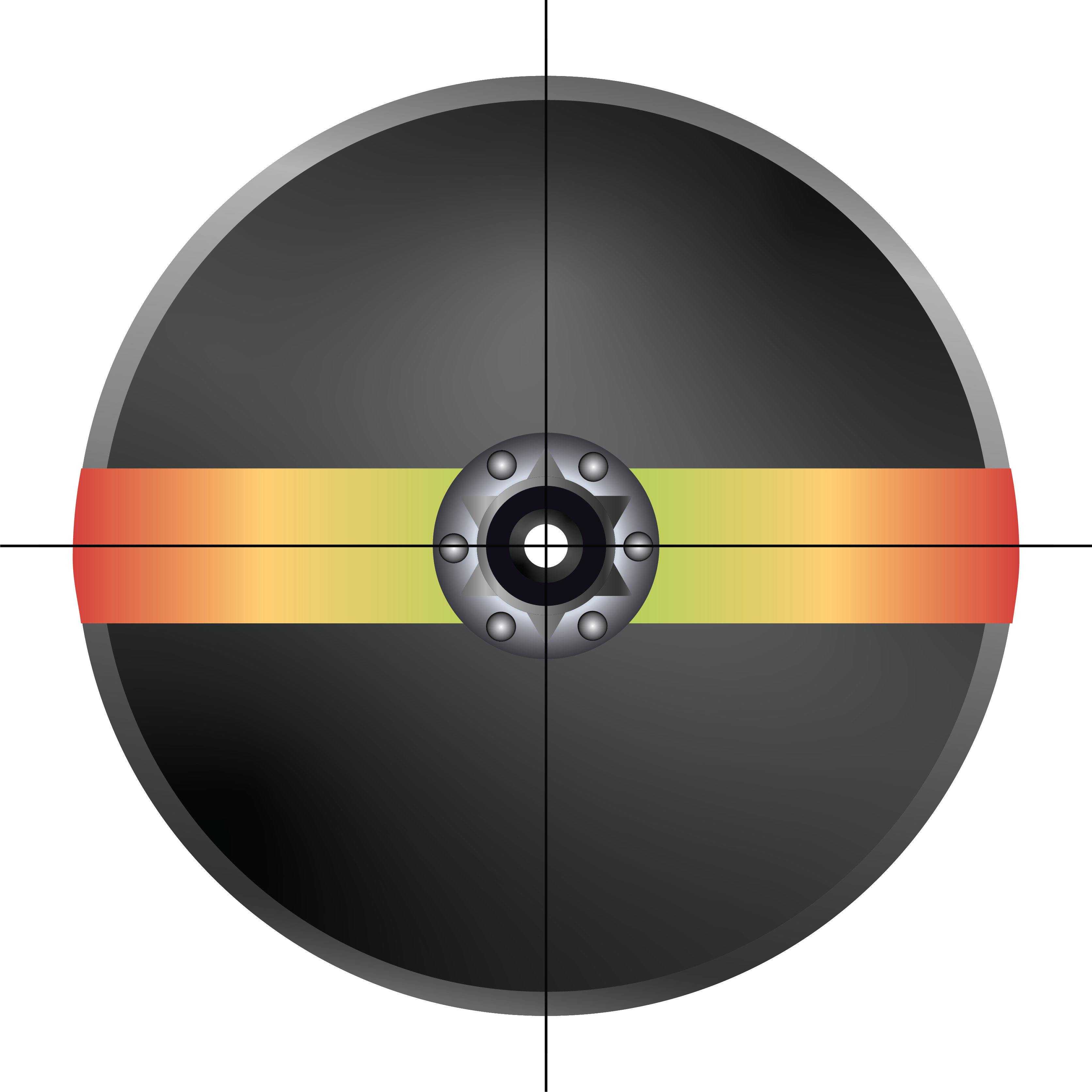

B-TOEM VS OEM Blades

Comparison of B-TOEM VS Other Blades

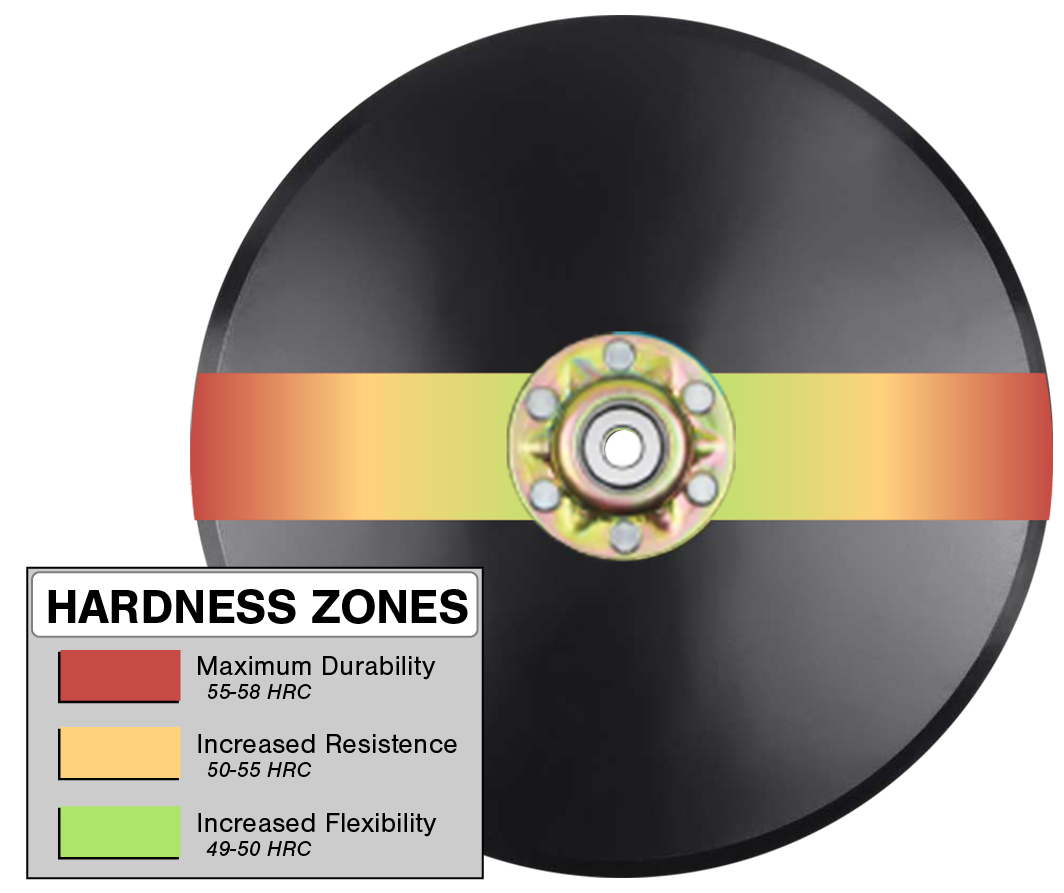

- B-TOEM Blades’ center has a 49-50 HRC then moving to the edge gains a 55-58 HRC.

- This allows the center to be flexibile, avoiding breakage, while retaining hardness along the blade edge to break down rocks.

- Other blades keep a 49-50 HRC throughout the whole blade, making them susceptible to breakage due too thier stiff nature.

- B-TOEM are pressed with bigger 5/16″ rivets, while others have 1/4″ rivets.

- B-TOEM uses 205 Double row, PEER bearing 5/16″ ball bearing. While other brands uses Standard 204 double row bearing 1/4″ ball bearings.

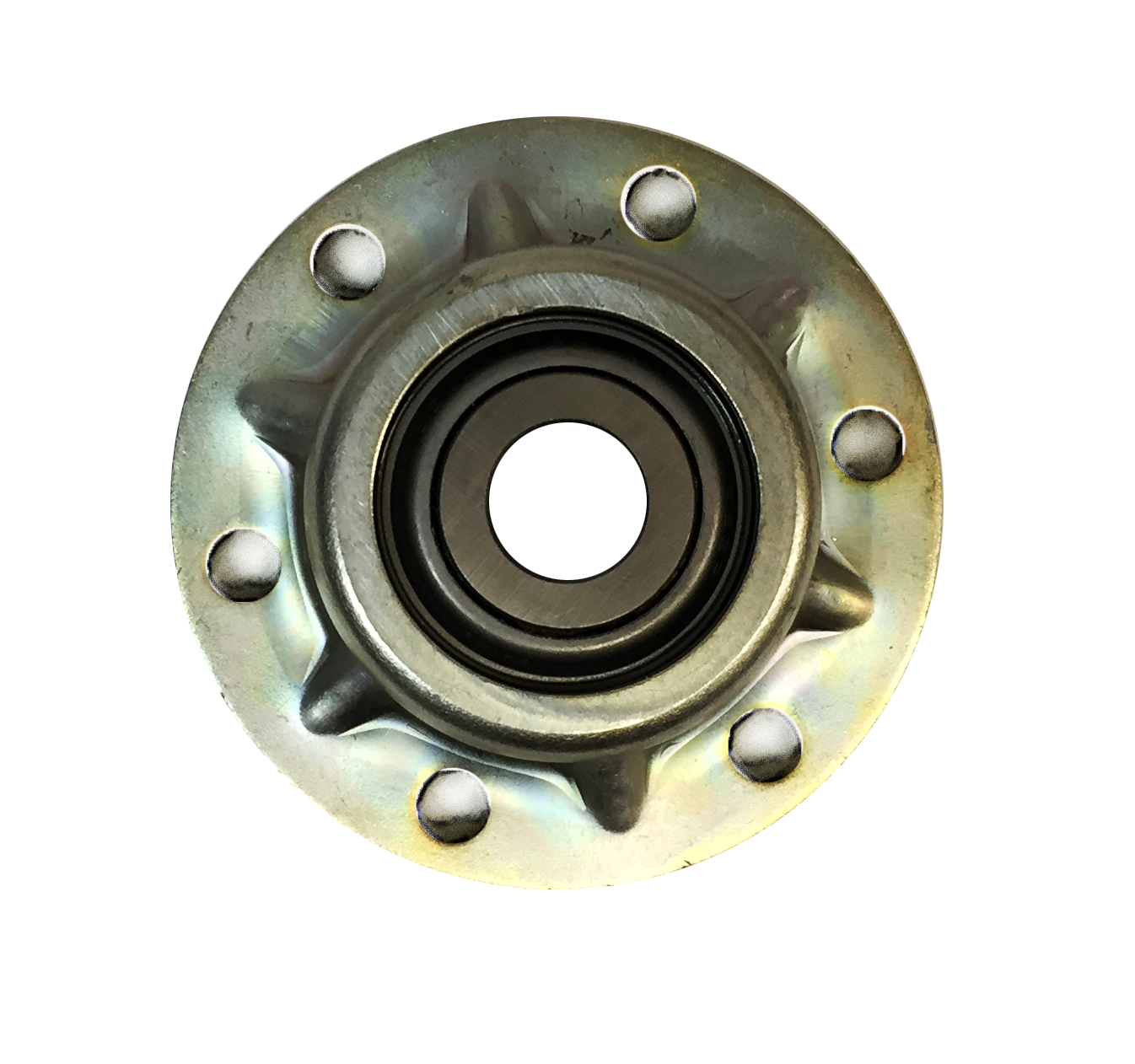

- B-TOEMs have a heavy duty hub, while others use the standard hubs.

B-TOEM Quality

To test durability, the B-TOEM blades were tested across rocks at 8 MPH with full down pressure.

B-TOEM blade has the same dimensions as an OEM blade; however the differences are impactful.

As these blades are used, thier doubled rolled beveled edges wear sharper and hold thier edge longer, retaining 20% more diameter on average than standard and competitor blades. The core of the B-TOEM blades is about 10% harder than other blades.

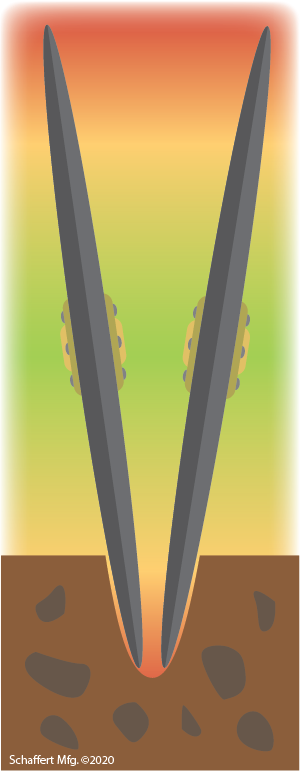

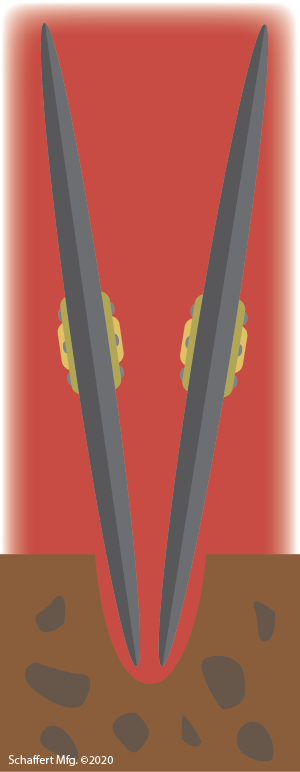

B-TOEM blades provide better blade to soil contact, as they do not roll over or break in rocky soils. These patented, heat treated blades have a heavy duty hub and are made of materials superior to those found in standard disc blades, giving them an improved and longer life.

This allows you to place seeds into harder soils, while maintaining flexibility to resist breakage in tough residue and rocky terrains.

B-TOEM has deep 3/4″ bevels, while other brands have 5/8″ bevels in the blades.

B-TOEM stays sharper longer. Being made out of a special high grade quality steel, the additional wear doesn’t effect the toughness of the blade. Other brands usually use 15B30 steel that can’t handle additional hardening. As the B-TOEM blade goes through wear, it is hardened on the outer edge about an inch into the blade.

This is important for two reasons:

- It handles the hardening better, lengthening the strength and sharpness of the blade.

- The whole blade is not hardened, just the edges. This allows the blade to continue being flexible avoiding breakage from rocks and foliage.

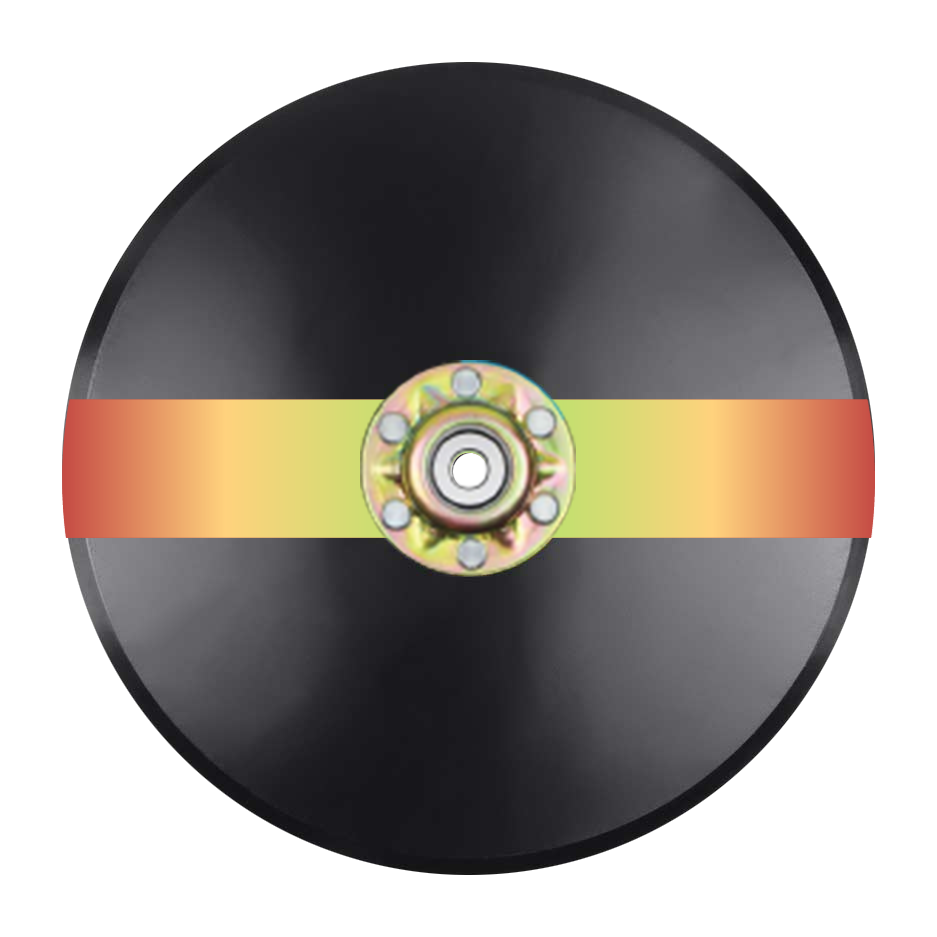

B-TOEM Bearing & Hub

B-TOEM

- Larger diameter, double-row 205 bearings

- 1/4″ Rivets

- Hub is finish-machined; being stamped on, creating a precise fit

- Bearing won’t be loose in hub, or too tight (either could shorten bearing life)

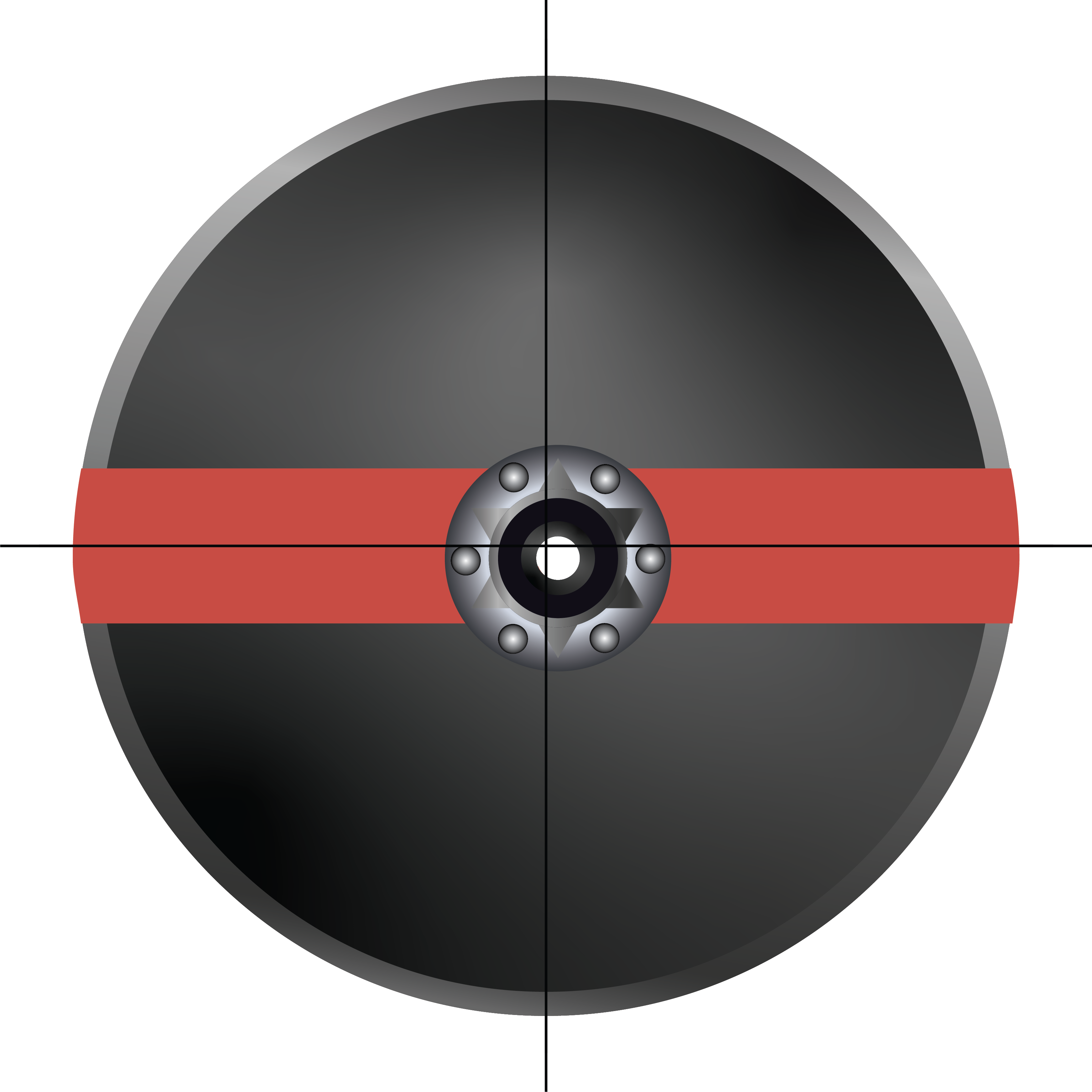

Other

- Small diameter, double-row 204 bearings

- 5/16″ Rivets

- Hubs are often misaligned

- Bearings are either too loose or tight, shortening bearing life

Alignments

When a blade is being centered into the hub, some brands fail at this, setting them into misalignment. When a blade is misaligned, seed furrows and therefore seeds are set at different depths into the soil. This will affect growth rates making them inconsistant; sometimes delying crops days or weeks between proper harvest times.

Before the blade machining is finished, the center is established, then the rivet holes are placed. The hub is then stamped in creating a precise fit. This helps the bearing not fail prematurely from misalignment.

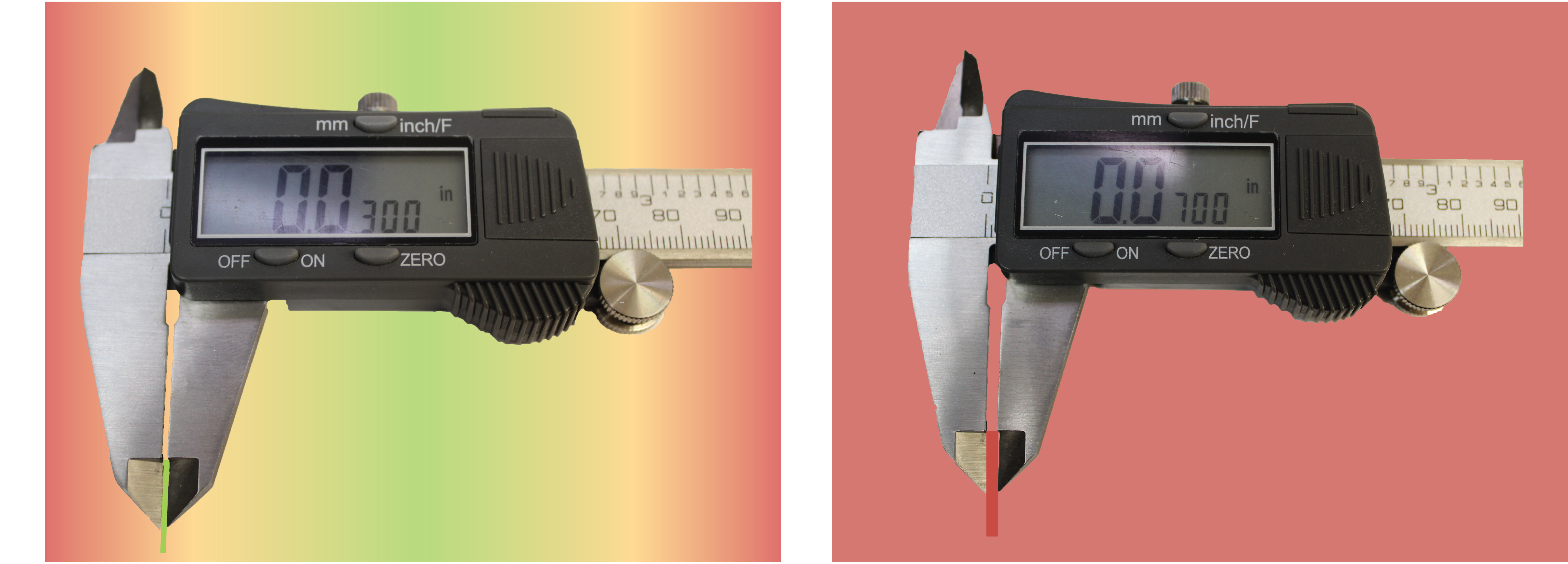

- B-TOEM can get as close as 300 mm centered

- Other brands are in the 700 mm center range

B-TOEM is centered, 300 mm. Other brands are off centered, 700 mm.