This is one of our earlier fertilizer tube attachments that we have put together for the John Deere 750-1990 No-Till Drills. As drills improved from the early 750s to the present-day 1990 drills, changes have been made.

This is one of our earlier fertilizer tube attachments that we have put together for the John Deere 750-1990 No-Till Drills. As drills improved from the early 750s to the present-day 1990 drills, changes have been made.

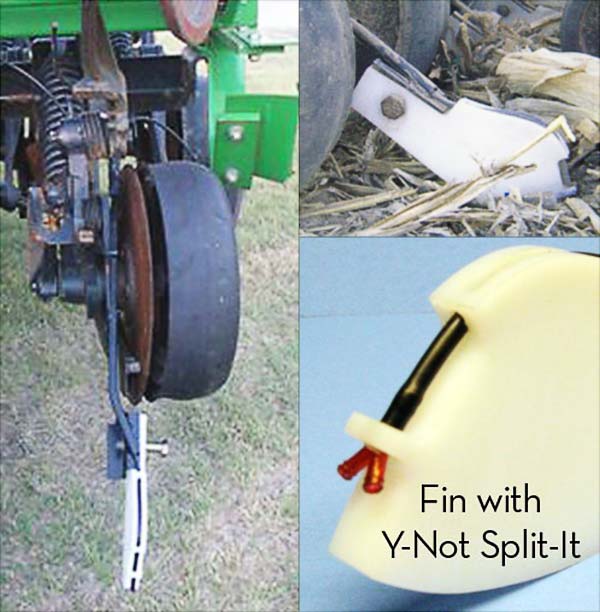

Early on we tried to run a stainless tube down the back of the seed boot and drop the fertilizer into the seed V ahead of the press wheel but the fertilizer would splash back on the press wheel, coating it and bearings with fertilizer. Then we added the Rebounder to the seed boot, replacing the seed flap that John Deere had. The seed flap didn’t have a concave design like the Rebounder does nor was it as thick as the Rebounder.

By putting the Rebounder on in place of the seed flap we helped put all the seeds in the bottom of the furrow as well as created a tab on top of the Rebounder to hold the fertilizer tube in the furrow. This helped keep fertilizer off the bearings of the press wheel, but it still let fertilizer build up on the press wheel tire itself. The press wheel would also rest on the Rebounder when the drill was in the up position and break the Rebounder off.

This prompted us to make a tube to go behind the press wheel tire. This worked fine as long as there wasn’t any trash involved. Where ever there was trash such as cobs and stalks they would get caught between the press wheel and the stainless tube and stop the wheel from turning.

This prompted us to make a tube to go behind the press wheel tire. This worked fine as long as there wasn’t any trash involved. Where ever there was trash such as cobs and stalks they would get caught between the press wheel and the stainless tube and stop the wheel from turning.

Other problems with the stainless tube over the press wheel were the cast closing wheel bracket would sometimes come down and bend the tube and bracket that went over the press wheel. This would happen if the farmer went over too steep of terraces or through too deep a ditch in the field.

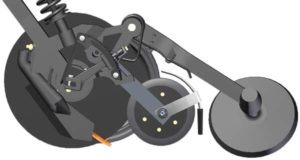

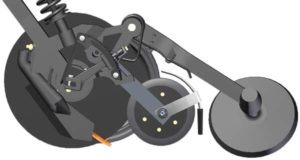

With several years under our belt and working with farmers we have modified the fertilizer tube over the press wheel to work and perform much better. Our new stainless steel fertilizer tube is easy to install and runs over and behind 9″ John Deere press wheels.

We also recently added a new heavy duty rubber boot to the bottom of the fertilizer tube. This boot is specially made for our fertilizer tubes, designed to immediately snap back into place after hitting trash. It works better than the drag hose previously used. The rubber boot also helps eliminate fertilizer on the row unit.

This is one of our earlier fertilizer tube attachments that we have put together for the John Deere 750-1990 No-Till Drills. As drills improved from the early 750s to the present-day 1990 drills, changes have been made.

This is one of our earlier fertilizer tube attachments that we have put together for the John Deere 750-1990 No-Till Drills. As drills improved from the early 750s to the present-day 1990 drills, changes have been made. This prompted us to make a tube to go behind the press wheel tire. This worked fine as long as there wasn’t any trash involved. Where ever there was trash such as cobs and stalks they would get caught between the press wheel and the stainless tube and stop the wheel from turning.

This prompted us to make a tube to go behind the press wheel tire. This worked fine as long as there wasn’t any trash involved. Where ever there was trash such as cobs and stalks they would get caught between the press wheel and the stainless tube and stop the wheel from turning.

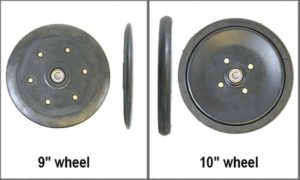

All the older John Deere Drills such as the 750 have 10″ press wheels and all newer drills like the 1890 and 1990s have 9″ press wheels. We recommend switching out the 10″ press wheel on older drills for 9″ press wheels.

All the older John Deere Drills such as the 750 have 10″ press wheels and all newer drills like the 1890 and 1990s have 9″ press wheels. We recommend switching out the 10″ press wheel on older drills for 9″ press wheels.