We have been updating our parts kits. Here is the newest version (2023) of instructions:

NEW STYLE/KITS PARTS for G SERIES

- G2 G3 G4 on 4LC

- G2 G3 G4 on OEM/Planters

- G2 G3 G4 on Great Plains

- G2 G3 G4 on Horsch Maestro

- G2 G3 G4 on John Deere

- G2 G3 G4 on Kinze

- G2 G3 G4 on Monosem

- G2 G3 G4 on White 6000-8000

- G2 G3 G4 on White 9000

- G2 G3 G4 on Yetter

- Stop Plates for G2 G3 G4

- G4 Closing Wheels on 4LC

- G4 Closing Wheels on OEM/Planters

- G3 Closing Wheels

- G4 Fertilizer Kit

- G4 No-Fertilizer Kit

Revolutionary Liquid Application System

Schaffert Mfg. Co. offers a revolutionary method of applying larger quantities of starter or nitrogen fertilizers, 2″-4″ to the side of the row and up to 2″ deep with our G2 fertilizer disc behind the planter.

About the G2

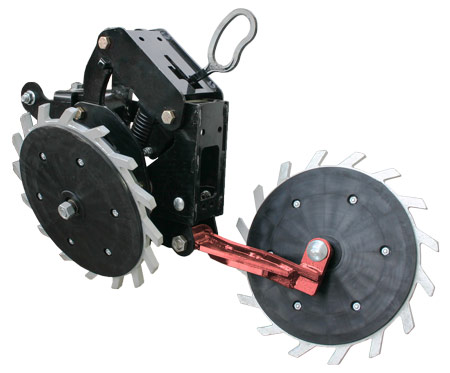

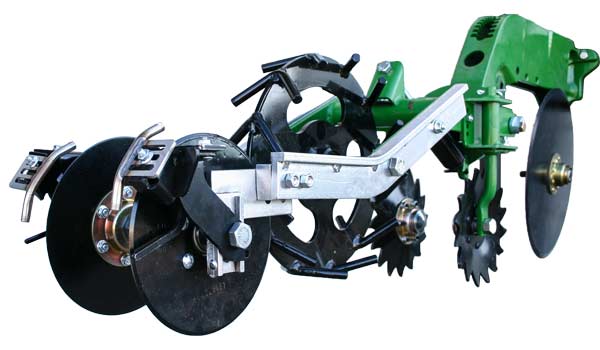

G2 shown with Mohawk closing wheels

The G2 fertilizer disc is an 8″ or 9″ single disc opener that is mounted on the press wheel brackets of John Deere, Kinze, White, Great Plains, Monosem, and Yetter planters.

For Case IH planters, use in conjunction with the 4 Link Closer or install our stainless steel single or dual side placement fertilizer tubes.

The G2 liquid disc is designed on a walking beam axle with 3 points of contact in the soil at all times. This patented walking beam design gives stability and balanced pressure to both press wheels in closing the seed V.

The G2 places fertilizer behind the planter. It provides even fertilizer depth in uneven terrains.

The G2 adds only 11 pounds per row added weight. It is easy to mount and easy to walk around the planter. The compact design eliminates having to find room in front or behind the planter for much larger, heavier, and more expensive fertilizer solutions.

The disc can be set to run 1/2″ to 2″ deep in the soil, and the G2 mounting bracket allows it at least 2″ more clearance under the tail section of the planter.

Right and left hand row units are available.

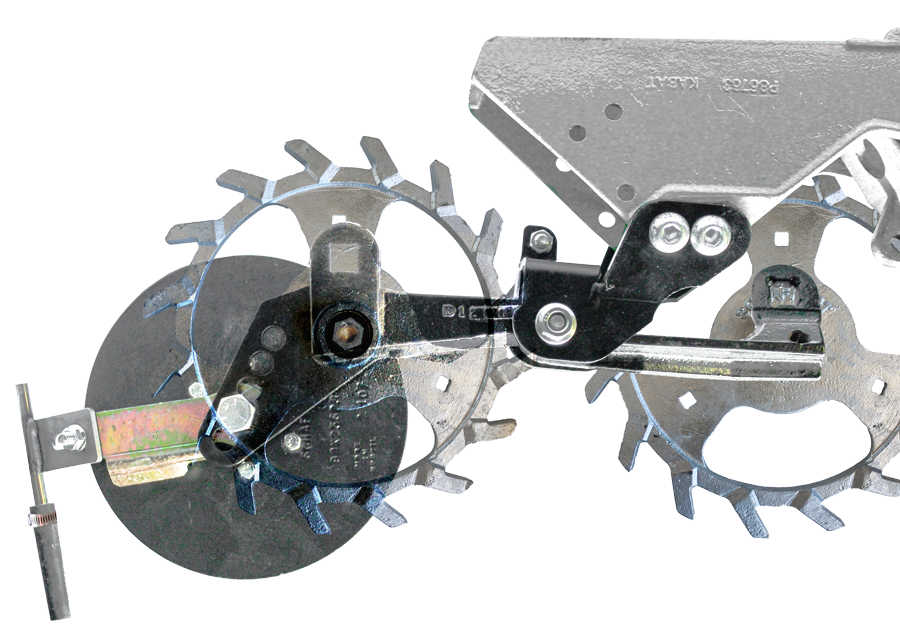

G2 with pivotable FAB bracket along with Zippers and the 4 Link Closer on a White planter

In a 3-year fertilizer application study (2011-2013) by Ken Ferrie of Farm Journal Magazine the G2 fertilizer disc topped their yield trials. (See charts)

Benefits of the G2

Close Coupled Design

Planter depth is controlled by the gauge wheels on a planter or drill. Most fertilizer attachments are 30″ to 36″ away from the seed drop thus making it hard to control depth of the planter unit in uneven ground. Our G2 fertilizer disc is placed between the gauge wheel and the press wheel. This makes it less than 12″ from the seed drop, keeping the planting unit running at a constant depth.

Features—Design—Benefits

- Unique one piece design that equalizes down pressure on press wheels and liquid disc

- A heavy duty triple sealed bearing utilized in the disc

- Powder iron oil impregnated bushings in walking beam

- Stainless axle in center pivot walking beam = no corrosion

- No drilling of holes on newer style JD, Kinze, White, Monosem, & Great Plains planters

- Single disc design for better penetration

- Adds only 11 lbs per row

- Easy to install

Eliminates Common Problems

- New liquid disc is tucked in behind the gauge wheel to keep it from plugging in heavy residue

- Will not disturb the seed—adjustable 2″-4″ away

- No need for extra heavy duty down pressure springs

G2 running with the high pressure kit and Zipper closing wheels

G3 & G4

G3 walking beam arm and Mohawk closing wheels on a Kinze planter

G3 WALKING BEAM ARM

Due to the popularity of our G2 walking beam axle, we created a similar walking beam, the G3, which is made to run without a fertilizer disc.

With the G3, farmers can still get the G2’s “walking” action of their closing wheels through the field, without having the addition of a fertilizer disc attachment.

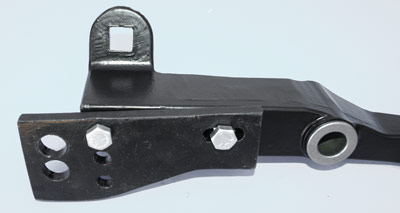

G4 WALKING BEAM

The NEW G4 walking beam axle offers the best of both worlds.

This is the option for farmers who sometimes want to apply fertilizer to the side of the furrow, and sometimes don’t.

The G4 walking beam is designed to easily add or remove the fertilizer disc. When the farmer is not applying fertilizer to the side of the furrow, they can simply remove the fertilizer disc and mounting plate to eliminate it catching trash or adding weight.

Removable mounting plate transforms the walking beam arm to run with or without a fertilizer disc

Pivotable Fertilizer Bracket & Rubber Boot

New “FAB” bracket

This new pivotable fertilizer bracket replaces the curved fertilizer tube and can be used on existing G2s.

The bracket pivots 40 degrees in and out from center so you can adjust and control where the fertilizer is injected, closer or further away from the disc blade.

The FAB bracket can be used for both low and high pressure. To run high pressure, simply screw in one of our stainless steel high pressure injector orifices into the bottom of the threaded tube. An injector orifice is included with the G2 kit.

We’ve also added a new heavy duty rubber boot to the bottom of the fertilizer tube. This boot is specially made for our fertilizer tubes, designed to immediately snap back into place after hitting trash. It works better than the drag hose previously used. The rubber boot also helps eliminate fertilizer on the row unit.

For Low & High Pressure

- Disc adjustable 2″-4″ from furrow

- NEW Fertilizer bracket pivots closer or further from disc blade

- Stainless steel tube injects fertilizer directly into the slice cut by the G2 fertilizer disc

- High pressure injector orifice threads into tube

- Adjustable trash deflector

- NEW Heavy duty rubber boot keeps fertilizer off the row unit

Fertilizer bracket pivots 40° in and out from center to control where the fertilizer is injected

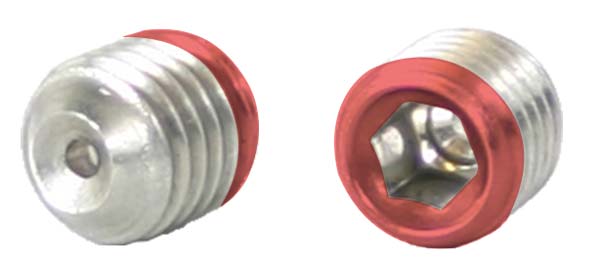

High Pressure Injector Orifice

Charts based on water and 30″ rows.

Schaffert Mfg.’s new high pressure injector orifice is made to screw into the end of the G2’s high pressure kit.

This kit works well with Schaffert’s hydraulic and electric-driven pump systems.

Features of the orifice include:

- Screws inside 3/8″ stainless tube

- Easy to install with an Allen wrench

- Orifice OD is 5/16″

- Stainless steel compact design

- 10 color coated orifice sizes

- Injects high pressure, 2-40 GPA

- Universal models – fits many machines

- Allows tube to be closer to soil surface, eliminating trash buildup

To find the correct injector orifice for your high pressure kit, you will need to know:

- Number of rows

- Row spacing

- Travel speed

- Pressure

- Kind of fertilizer

- Product weight

- Gallons per acre

PLEASE NOTE: We normally recommend using only 1 orifice under pressure when running 7-15 lbs of pressure. However, using 2 orifices under pressure can be beneficial because it will help eliminate fertilizer splatter or misting/volatilization of fertilizer when done in the following manner:

- Use the correct size orifice above for 15-30 psi pressures

- Use 2-3 times size orifice below, creating 5-7 lbs pressure to stream fertilizer into the soil

NEVER USE 2 OF THE SAME SIZE ORIFICES IN YOUR SYSTEM!!!

DO NOT run orifices with squeeze pumps. This cannot be done because squeeze pumps do not put out enough pressure for an orifice system. Squeeze pumps only put out 2-3 pounds of pressure.

Dual Side Placement

For dual placement of nitrogen, phosphate, potash, and micro-nutrients when planting cotton, corn, peanuts, or soybeans

Dual side placement of fertilizer is quickly becoming a popular method of increasing yields. Traditionally, side placement of fertilizer has occurred on one side of the furrow. But with our new dual options, farmers can now apply liquid fertilizer on both sides of the furrow.

Add another tube to your new or existing G2 fertilizer disc to place liquid on the opposite side of the furrow (shown here on a John Deere planter).

G2 dual placement with Zippers on a John Deere planter

Dual G2 with Chicken Tracker on a John Deere cotton closing attachment

Original John Deere cotton closing unit (part #BA270006)

Notched Disc for Heavy Residue

This notched G2 fertilizer disc works well when planting into wet or dry heavy residue field conditions (such as soybean stubble and heavy corn residue).

The notches in the blade help it “walk” over the residue, keeping the disc rolling in the field instead of plugging or stopping.

This specialized G2 is a true mud hog. In some conditions, using the notched style blade will allow you to eliminate the residue scraper.

Stalk Deflector

JD 1700 planters mounting instructions

JD 7000/7100/7200/7300 & Kinze planters mounting instructions

Conversion Kits

After much demand, Schaffert Mfg. designed a bracket that works like the newer John Deere planters. We now offer G2 fertilizer disc conversion kits for older style John Deere 7000/7100/7200/7300 series planters and Monosem 2001 and newer planters that will allow the G2 to fit them.

Check your tail section to see if it has two holes at the bottom to offset press wheels. If it does not, you will need to order the conversion kit along with the G2.

John Deere 7200/7300 planters will not need new press wheels because they already have the correct bearing for our G2 kit. The only ones that need to have new wheels are the ones with water pump type bearings.

G2 Tops Farm Journal Yield Trials

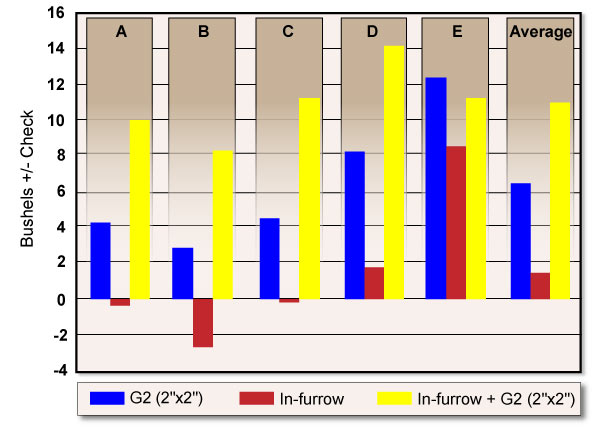

2013 YIELD BY SOIL TYPE COMPARED WITH CHECK

In a 3-year fertilizer application study by Ken Ferrie of Farm Journal Magazine the G2 fertilizer disc topped their yield trials.

In four of the five soil types, yields increased when starter was applied 2″ to the side of the seed in-furrow, using the G2 fertilizer disc. With the dual placement of fertilizer for the young corn plant, this creates a relay effect as the different fertilizer bands are reached.

Source: Eckelkamp, Margy. “Smooth Hand-Off.” Farm Journal Magazine. 25 Jan 2014. www.agweb.com/article/smooth_hand-off_NAA_Margy_Eckelkamp

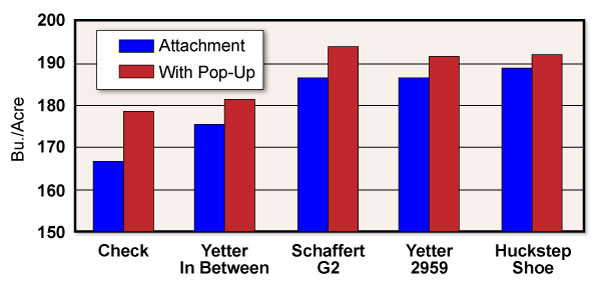

ADDING POP-UP IN 2012 PUSHED G2 YIELDS TO TOP

Each of these attachments provides a different placement relative to the seed and mounts differently on the planter. In 2012, there was an above average response to including pop-up fertilizer across two corn-on-soybean fields in central Illinois.

Source: Eckelkamp, Margy. “Starter Test Plot Roundup.” Farm Journal Magazine. 26 Jan 2013. www.agweb.com/article/starter_test_plot_roundup

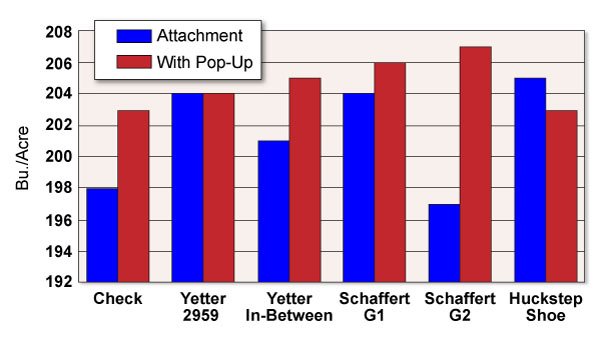

ADDING POP-UP IN 2011 PUSHED G1, G2 YIELDS TO TOP

This chart displays the average yield results across two corn-on-corn fields in central Illinois. The farther the starter was placed outside the furrow, the more likely that adding pop-up starter in-furrow would increase yield.