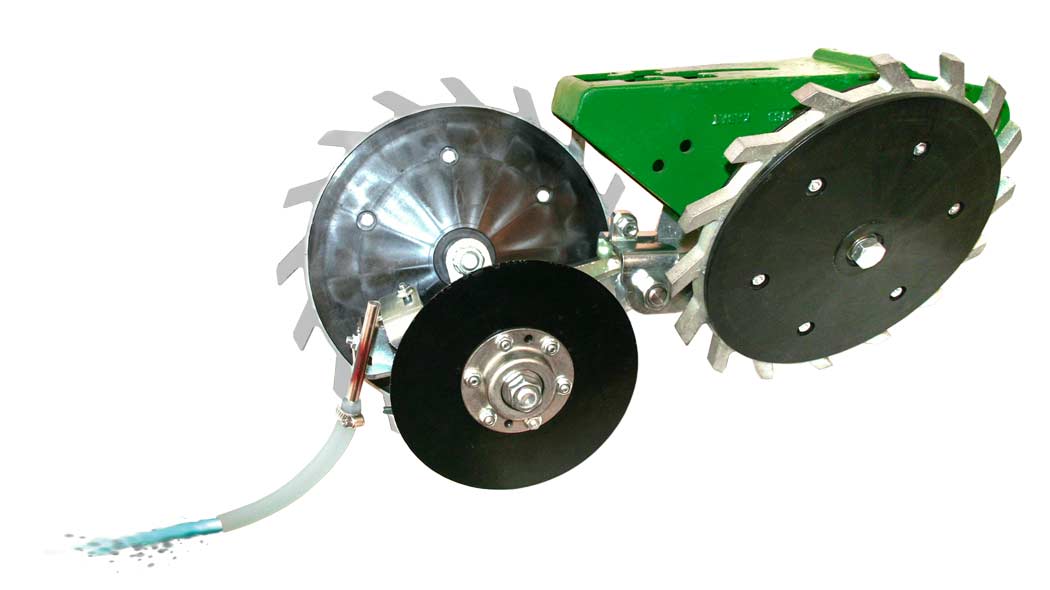

Angled spiked closing wheels

Mohawk Wheel

Mohawk Wheel

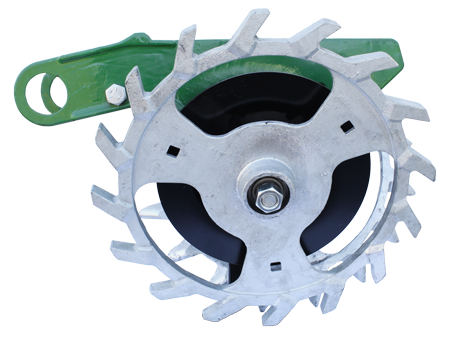

Cast Mohawk

Cast Mohawk

Cast Mohawk Max

Cast Mohawk Max

Standard, rubber closing wheels have a tendency to press the soil closed causing a smooth effect, especially when the soil is wet. On a hot, dry windy day, the furrow will crack back open exposing the seed. Eliminate this problem with the Mohawk Closing Wheel.

About the Mohawk

The Mohawk is a 13″ angled spiked closing wheel designed to take the place of standard, rubber closing wheels. It works in all soil types, most notably in the toughest of no-till conditions.

The Mohawk is a 13″ angled spiked closing wheel designed to take the place of standard, rubber closing wheels. It works in all soil types, most notably in the toughest of no-till conditions.

The non-aggressive, 1″ angled blunt spikes on the Mohawk feather the soil in the furrow while simultaneously applying light pressure to ensure the furrow is stitched shut.

As the spikes close they create indentations which allow moisture to sink in, increasing seed-to-soil contact.

Mohawk closing wheels are angled so that when they engage the soil at the 5, 6, and 7 o’clock positions, they are breaking the side wall down over the seed plus compacting the soil around the seed. Then, when they exit the soil at the 8 o’clock position, they are angled such that they release the soil, leaving it compacted around the seed. Because of this, you will not need to drag a chain behind them.

Other closing wheels on the market are aggressive and have the potential of actually flipping seeds out of the furrow. You will not have that problem with the Mohawk.

Farm Journal agronomist Ken Ferrie conducted a three-year study examining closing wheel designs, including the Mohawk. He classified the Mohawk as a firming spiked closing wheel, which are designed to provide both crushing action of the sidewall and firming above and around the seed. Ferrie concluded that in the toughest no-till conditions, wheels like the Mohawk get the job done the best.

Source: Eckelkamp, Margy. “Test Plots: Close and Seal the Deal.” Farm Journal Magazine. 9 Feb 2013. www.agweb.com/farmjournal/article/test_plots_close_and_seal_the_deal

Benefits of the Mohawk

Features—Design—Benefits

- Stitches seed V shut

- Uses existing wheels and bearings, and replaces tire with the Mohawk ring, saving you $$$

- Breaks down compacted sidewall and closes the furrow at the same time

- Longer wear, heavy duty cast steel spikes

- Feathers the soil in the seed V with its wide track design

- Designed to break up compaction without being too aggressive

- 1″ spike will not get too close to or disturb seed

- Allows for better seed-to-soil contact

Eliminates Common Problems

- Compacts the soil better than straight-fingered wheels

- Moves soil with minimal compaction into the furrow

- Eliminates air pockets

- On a hot windy day the trench will not break back open

Where They Work—Suitable for Many Soils

- Made to work in tough soils

- Works in no-till or conventional

Ease of Installation

- Easy to install

- Can be used with or without the G2 liquid fertilizer disc

The NEW all-cast Mohawk Closing Wheel won’t build up with mud due to not having plastic rims catching mud on each side.

We experimented with these in 2019 in very wet soils and farmers were impressed with how clean they stayed in wet sticky soils.

COVER CROPS

Many of the spiked wheels on the market wrap or plug in cover crops. The cast Mohawk is less likely to plug or wrap in heavy cover crops.

If they do start to wrap, one can order Hub Covers (shown here) as an option to prevent wrapping of cereal rye, vetch and other vining crops

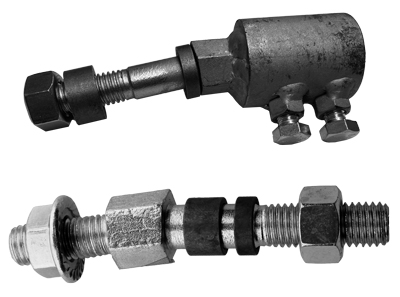

CAST WHEELS FOR DRILLS

Schaffert Mfg.’s all-cast wheels are an excellent option for John Deere and Case IH drills.

Included in the cast wheel kit for these drills is an eccentric bolt that changes the pitch in on the back side of the closing wheel. This allows the wheel to bring soil in into the furrow behind the wheel, compacting it down around the seed.

Please note that the Case IH 500 eccentric bolt kit has been updated since the video above was created. The new eccentric bolt works in the same manner.

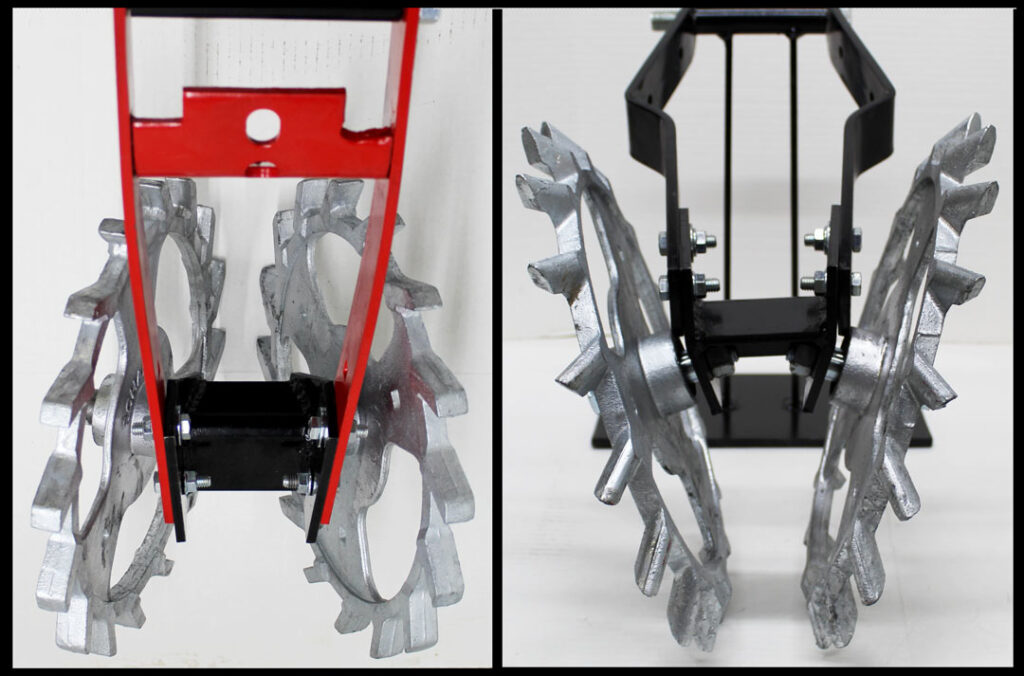

SINGLE TO DUAL WHEEL CONVERSION KITS

We have conversion kits that transform your single press wheel to dual closing wheels. Works great with our Mohawk and Zipper wheels.

Kits fit Case IH and White 5000-6000 series planters.

In the Field Performance

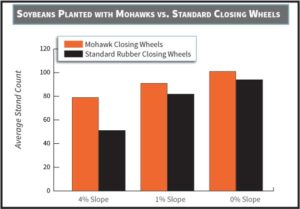

MOHAWKS VS STANDARD CLOSING WHEELS

This graph shows data from a field of soybeans planted on May 29, 2013 near Ponca City, OK with Black Machine tool bar equipped with John Deere 7200 Max Emerge II row units. Some rows had standard rubber closing wheels and some had Mohawk Closing Wheels.

This graph shows data from a field of soybeans planted on May 29, 2013 near Ponca City, OK with Black Machine tool bar equipped with John Deere 7200 Max Emerge II row units. Some rows had standard rubber closing wheels and some had Mohawk Closing Wheels.

2.5″ of rain fell on the field a week after planting, causing erosion down the rows even though the farm had not been cultivated in 5 years.

Stand counts were taken June 15, 2013 on varying degrees of slope down 36′ row.

The steeper the slope the greater the erosion of the soil down the furrow, and the less stand counts behind the regular closing wheels.

MOHAWK AFTER 1500 ACRES

The following photos show a Mohawk closing wheel that has been run 1500 acres and is still in excellent condition.

MOHAWK AFTER 9000 ACRES

The following photos show a used Mohawk closing wheel next to a brand new Mohawk ring. The wheel has been run 9000 acres and is still in good working condition. Wheel courtesy of John Yeutter, Eustis, NE.

Mohawk Distinct Features Over The Zipper

- Creates a flat ice cream cone shape with the soil in and above the seed V (the Zipper creates a more rounded ice cream cone shape)

- Slightly less aggressive than the Zipper

- Mohawks are more economical when using your existing wheels and bearings

Mohawk ring only

Mohawk ring only