Side Placement Fertilizer Tubes for Case IH 2100

Benefits of Dual Side Placement

- Double your rate of fertilizer while keeping it in two separate bands close to the furrow to propagate downward root movement

- Lower rate versus broadcasting for zone building

- Safer at higher rates for seedlings

- Great for micro-nutrient packages of fertilizer that cannot go in furrow

- Located behind the cover discs on the planter, keeping the gauge wheels clean for better depth control—no build-up from opener in front of the row unit

- Works excellent with the 4″ Chicken Tracker™ press wheel―helps eliminate mud build-up

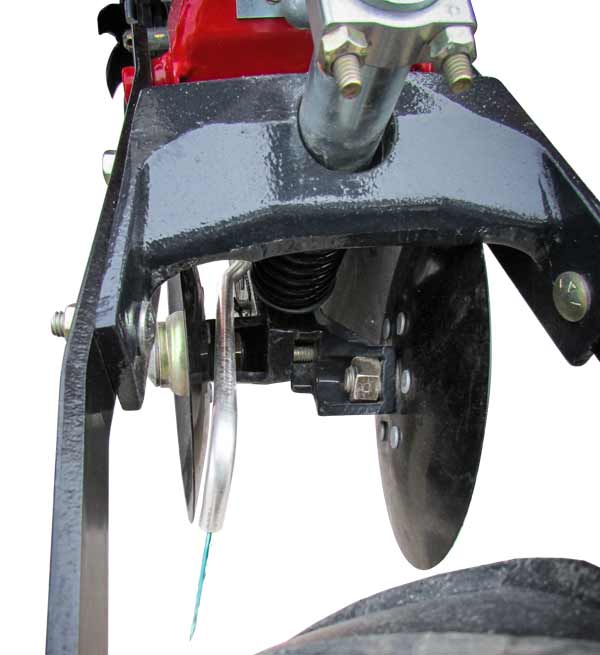

When using in-between tubes, the liquid fertilizer injects directly into the slices opened by the Case IH cover discs.

Out the Back for Case IH 2100 comes with two tube options, bent or straight. The bent tubes place the liquid closer in to the center of the furrow.

For high pressure, screw in one of Schaffert Mfg.’s stainless steel high pressure injector orifices into the bottom of the tube.

The heavy duty rubber boot is specially made for our fertilizer tubes, designed to immediately snap back into place after hitting trash. The rubber boot also helps eliminate fertilizer on the row unit.

We have different connector hose and Y-splitter options available for single and dual placement.

Benefits of Dual Side Placement

- Double your rate of fertilizer while keeping it in two separate bands close to the furrow to propagate downward root movement

- Lower rate versus broadcasting for zone building

- Safer at higher rates for seedlings

- Great for micro-nutrient packages of fertilizer that cannot go in furrow

- Located behind the cover discs on the planter, keeping the gauge wheels clean for better depth control—no build-up from opener in front of the row unit

- Works excellent with the 4″ Chicken Tracker™ press wheel—helps eliminate mud build-up

- Different hose size options to find your perfect fit

Side Placement Fertilizer Tubes for Case IH 800-1250

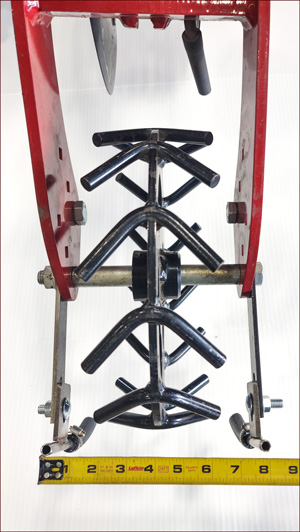

This fertilizer tube mounts directly to Case IH 800-1250 series planter units and moves independently of the covering disc bracket.

Its compact design injects fertilizer directly into the slice opened by the Case IH leading cover disc.

The tube places fertilizer precisely where you want it to the side of the row, giving roots early access to the nutrients needed for optimal plant growth.

The fertilizer is incorporated into moist soil, so it will not splash on the planter, press wheels, or on top of the ground.

This eliminates mud building up on the standard or Chicken Track press wheels.

Benefits of the Side Placement Tube

Side Placement of Fertilizer

- Injects fertilizer into furrow on one or both sides of the furrow

- Incorporates fertilizer into moist soil

- Puts fertilizer in slice or opening made by cover disc

- Optional to add high pressure tips

How It Mounts

- Formed compact tube bolted to unit

- Mounted directly to planter, NOT to cover discs

- Fertilizer hose attaches high up on planter

- Rights and lefts available

Eliminates Common Problems

- Eliminates fertilizer on planter, press wheels, and on top of ground

- Helps eliminate catching trash

Dual Side Placement for Case IH 800-1250

For dual placement of nitrogen, phosphate, potash, and micro-nutrients when planting cotton, corn, peanuts, or soybeans

Dual side placement of fertilizer is quickly becoming a popular method of increasing yields. Traditionally, side placement of fertilizer has occurred on one side of the furrow. But with our new dual options, farmers can now apply liquid fertilizer on both sides of the furrow.

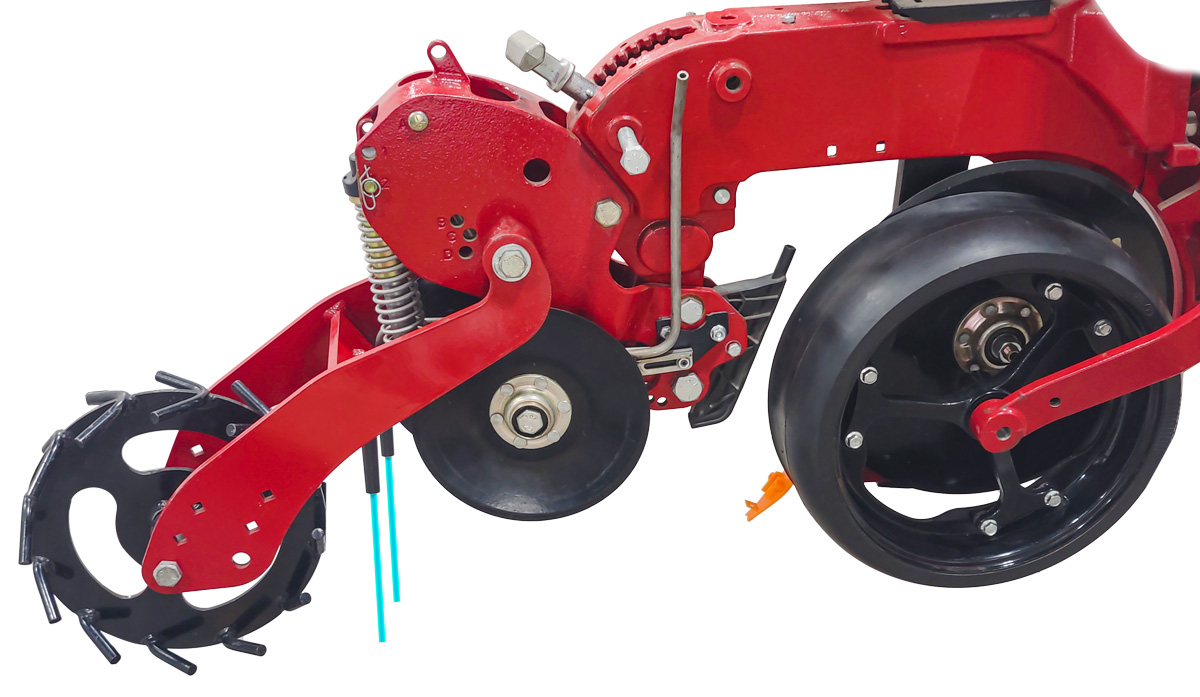

Dual fertilizer tubes with the Rebounder and Chicken Tracker on a Case IH 1200 planter

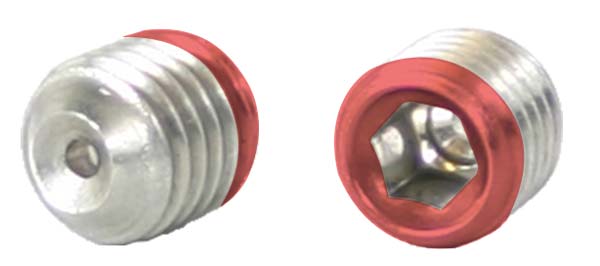

High Pressure Injector Orifice

Orifice end (left) and hex end (right)

Schaffert Mfg.’s new high pressure injector orifice is made to screw into the end of this side placement fertilizer tube.

This kit works well with Schaffert’s hydraulic and electric-driven pump systems.

Features of the orifice include:

- Screws inside 3/8″ stainless tube

- Easy to install with an Allen wrench

- Orifice OD is 5/16″

- Stainless steel compact design

- 10 color coated orifice sizes

- Injects high pressure, 2-40 GPA

- Universal models – fits many machines

- Allows tube to be closer to soil surface, eliminating trash buildup

To find the correct injector orifice for your high pressure kit, you will need to know:

- Number of rows

- Row spacing

- Travel speed

- Pressure

- Kind of fertilizer

- Product weight

- Gallons per acre

- Use the correct size orifice above for 15-30 psi pressures

- Use 2-3 times size orifice below, creating 5-7 lbs pressure to stream fertilizer into the soil

NEVER USE 2 OF THE SAME SIZE ORIFICES IN YOUR SYSTEM!!!