This simple yet effective planting attachment improves the accuracy and uniformity of in-furrow seed placement by funneling all seeds to the bottom of the seed V.

This simple yet effective planting attachment improves the accuracy and uniformity of in-furrow seed placement by funneling all seeds to the bottom of the seed V.

The Rebounder has a unique, spoon shape design that forms to the V shape of the furrow. This works in conjunction with the furrow’s V shape rather than against it. Many of the firming products on the market today work against this theory, especially in tougher clay type soils. They create additional sidewall compaction as they press through the seed V applying pressure.

The Rebounder’s spoon shape design flows gently down the furrow, not disturbing the soil or creating any additional compaction around the seed. The spoon shape design gradually narrows as it drops below the top soil surface to follow the V shape that is created by the double disc openers.

The distinct half moon notch on the bottom tip of the Rebounder allows it to run 3/8″ off the bottom of the furrow. Because the Rebounder does not drag the bottom of the seed bed, it will not drag seeds or build up with mud.

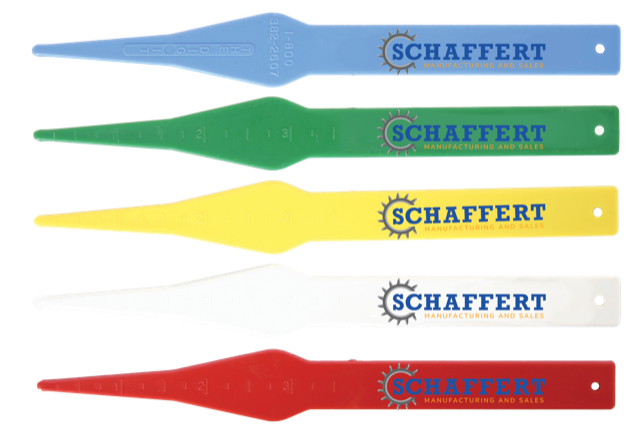

Installing the Rebounder is quick and easy. We have a Rebounder for most models of planters and drills.

On most planters the Rebounder attaches to the seed tube. It is designed to serve as an extension of the seed tube, and works with the seed tube rather than against it. The Rebounder functions as a stabilizer that keeps the seed tube in the center of the furrow.

When mounted to the seed tube, the Rebounder puts less than 1 pound of pressure on the seed tube while planting. This small amount of pressure in the seed furrow eliminates mud from building up when planting in heavy, wet textured soils. Other attachments on the market place approximately 1.5 pounds of pressure on the seed. This pressure on the seed pushes it deeper in softer soils and leaves it shallower in firmer soils, creating a wave effect in the depth placement which causes uneven emergence.

The Rebounder funnels seeds to the bottom of the seed V, eliminating seed bounce, seeds flipped on top of the soil, and uneven spacing. It produces uniform seed placement and accurate depth control. This leads to improved germination and consistent emergence, generating higher yields through healthier plants.

This simple yet effective planting attachment improves the accuracy and uniformity of

This simple yet effective planting attachment improves the accuracy and uniformity of