Q&A

Will the Rebounder improve the performance of my drill?

Yes—Many drill owners say that after putting on the Rebounders they no longer see seeds out of the trench. Even farmers who use a drill with Rebounders to plant alfalfa say they can find a high percentage of alfalfa seeds in the bottom of the seed furrow. Without the Rebounders they hardly find any of the seeds because they are mixed throughout the seed trench.

The Rebounders will pay for themselves in less than 100 acres in seed savings alone. People have said they backed off their soybean seeding rates with a drill with Rebounders by as much as 70,000 seeds per acre, and yet still meet their yield potential. With the high cost of seed these days this can put money back in your pocket.

Does the Rebounder pull soil in with the seed?

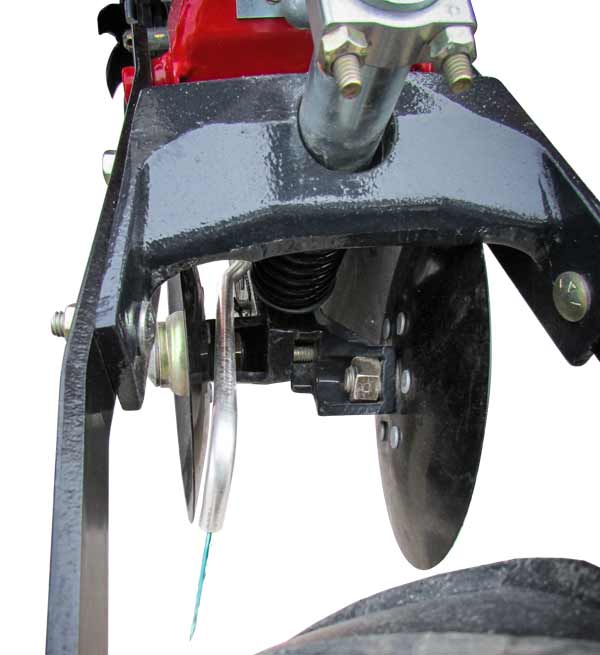

No—The only time the Rebounder puts soil with the seed is in heavier wetter soils when the double discs that open the seed V orange peal the sidewall of the seed V. When this occurs this is where the Rebounder shines over other attachments because it is shaped like the seed V it will peel the lodged seeds off the orange peeled side wall funneling them to the bottom.

Does the Rebounder pull loose dry soil off the soil surface and place with the seed?

No—The Rebounder enters the seed V directly behind the double disc openers and ahead of the gauge wheels that run along side the seed V. This lets the Rebounder put all the seed in the bottom of the seed V before the gauge wheels cave any dry soil in over the seed. The Rebounder assures you better germination being in the bottom of the V with moisture on 3 sides of the seed and dry soil on top.

Does the Rebounder leave seeds stranded on the side wall of the seed V or press them in the side wall when they lodge along the side?

No—The patented concave design and shape of the Rebounder eliminates seeds from being stranded on the side wall. The Rebounder puts the seeds in the center of the bottom of the furrow. Other attachments with flat bottoms or rounded surfaces sometimes can leave seeds lodged in the sidewall. As one farmer put it when using other attachments, “It’s like stacking two ball bearings or two marbles and try pressing them into the soil—you never know where they will end up.”

Does the Rebounder need to be adjusted for proper tension in the seed V?

No—The Rebounder was designed out of plastics that have an automatic flexibility built into them to compensate for the different soil types and conditions one might be running them in. This designed flexibility was built in above the spoon area and below the tie or bolted area of the Rebounder. This Rebounders simple design eliminates the need for built in tension adjustment that make it confusing in different soil types and soil conditions to adjust.

Why does the Rebounder mount to the seed tube?

The Rebounder has been mounted to the seedtube ever since it was invented 10 years ago. The Rebounder puts very little pressure on the seed tube preventing damage to the seed tube. The Rebounders shape centers the seed tube in the seed trench behind the double disc openers, keeping the seed tube from rubbing and wearing on the discs. The Rebounder also steadies the seed tube keeping it from vibrating in its holder thus keeping seeds from bouncing in the seed tube.

Will the Rebounder drag seeds in the seed furrow?

No—As the double discs or True V openers of the planter make the seed V opening the Rebounders trailing end runs about 3/8″ off the bottom of the seed V. The Rebounder was designed to be wider than the bottom of seed V thus letting it flex up off the bottom about 3/8″. The half moon notch in the end of the Rebounder centers the seeds in the bottom letting them pass through without being drug along.

Does mud build up on the Rebounder when soil conditions are sticky?

No— The Rebounder does not put pressure in the bottom of the seed V where mud build up can occur in heavier wetter soils. We tell farmers that if they feel comfortable planting and it is wet that they don’t have to worry about the Rebounder building up with mud and dragging seeds. Part of the no mud build up is due to the flexibility built into the Rebounder above the spoon area.

This simple yet effective planting attachment improves the accuracy and uniformity of

This simple yet effective planting attachment improves the accuracy and uniformity of

Zipper

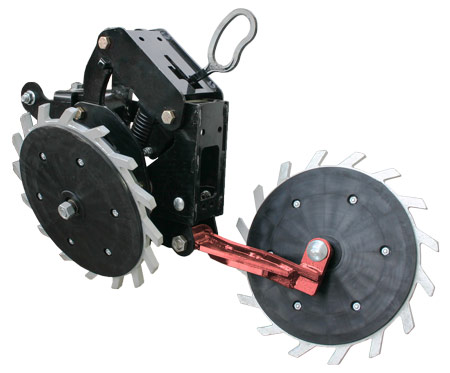

Zipper Cast Zipper

Cast Zipper Zipper Spyder™

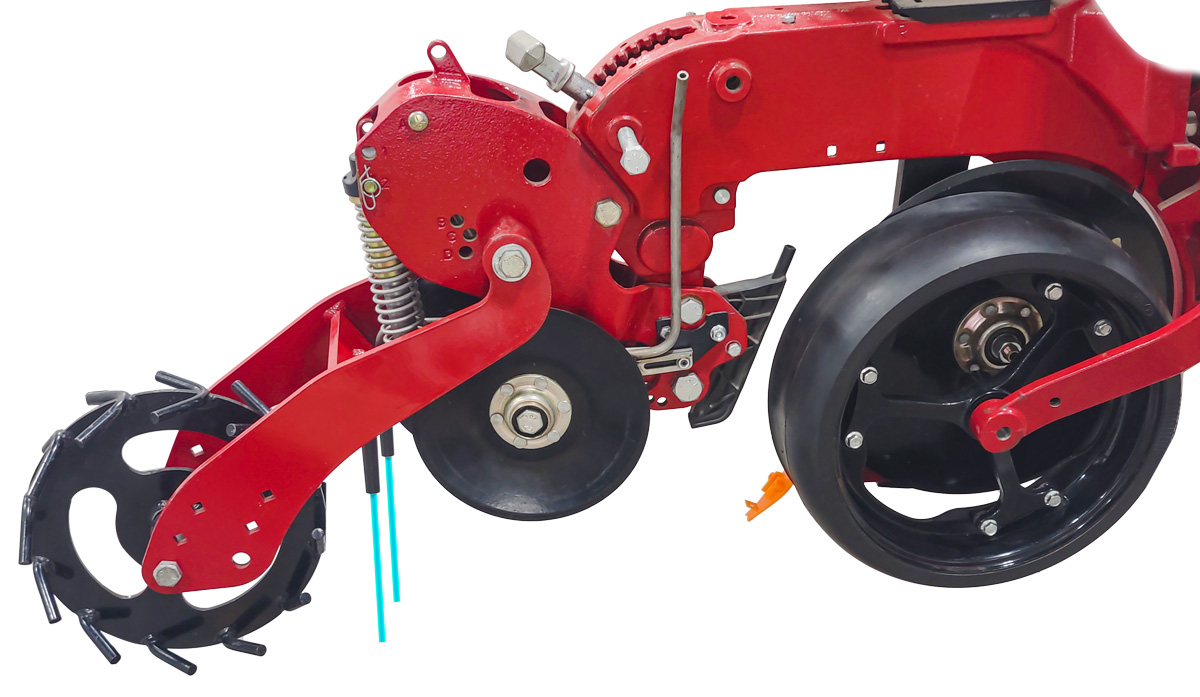

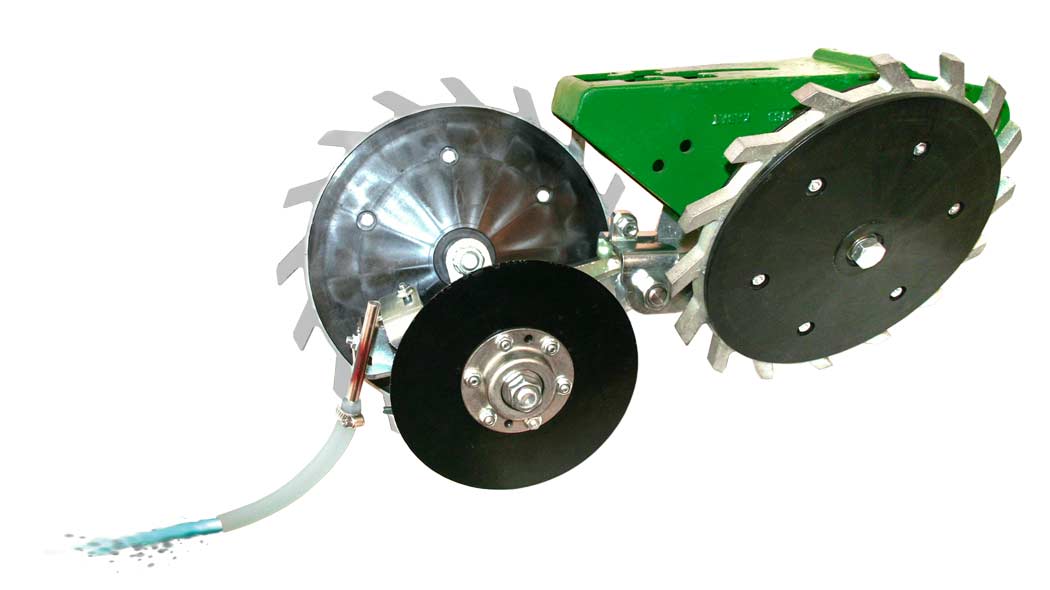

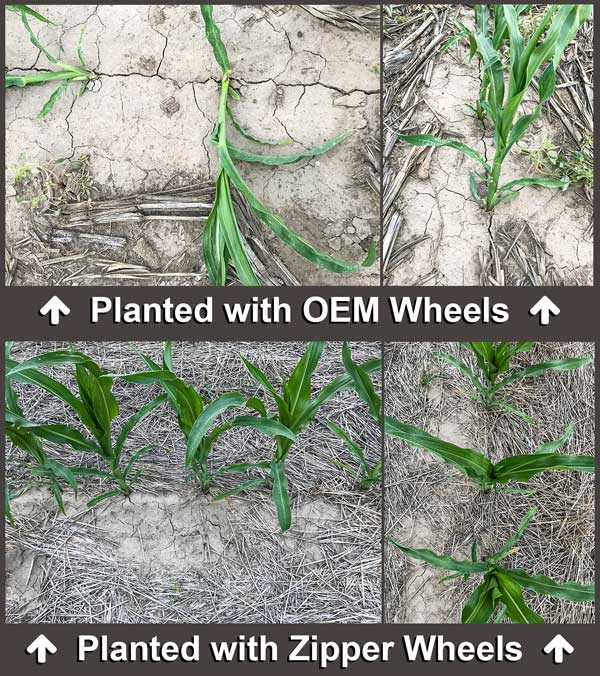

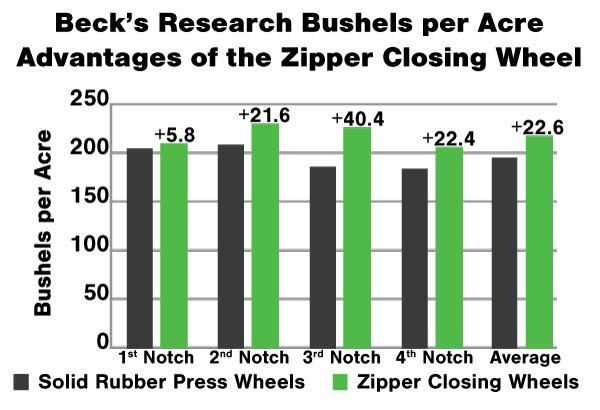

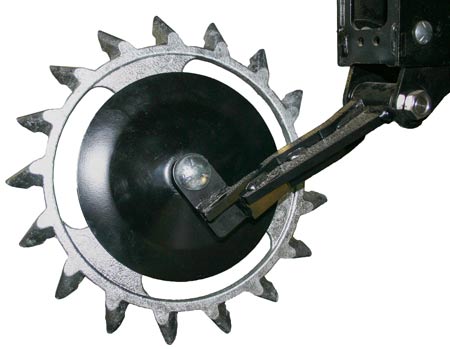

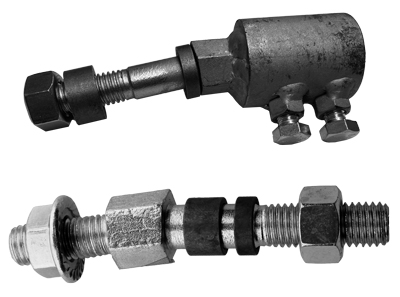

Zipper Spyder™ The Zipper is a 13″ angled spiked closing wheel designed to take the place of standard, rubber closing wheels. It works in all soil types, and is the go-to wheel for the toughest of no-till conditions.

The Zipper is a 13″ angled spiked closing wheel designed to take the place of standard, rubber closing wheels. It works in all soil types, and is the go-to wheel for the toughest of no-till conditions.

The

The

The

The

Mohawk ring only

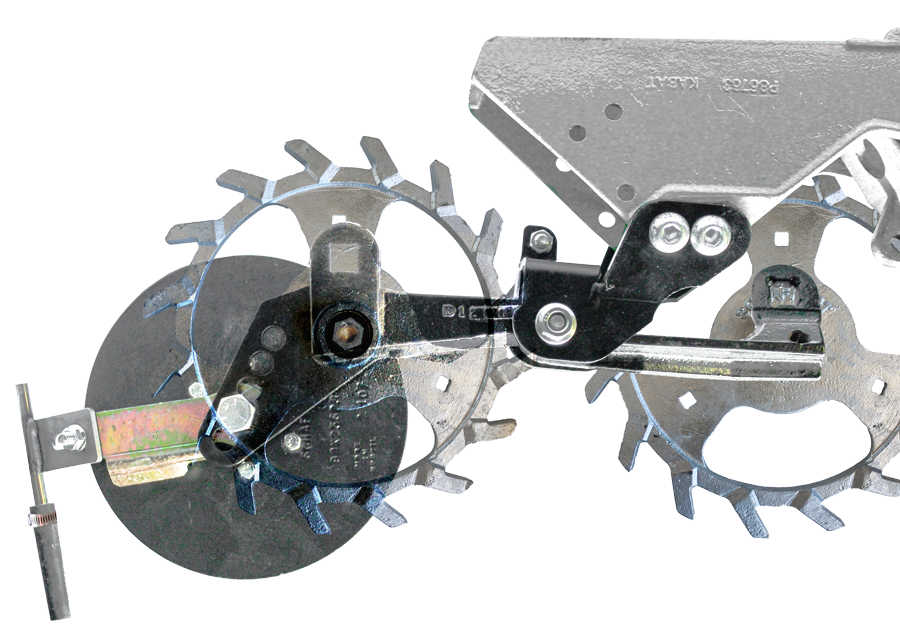

Mohawk ring only Mohawk Wheel

Mohawk Wheel Cast Mohawk

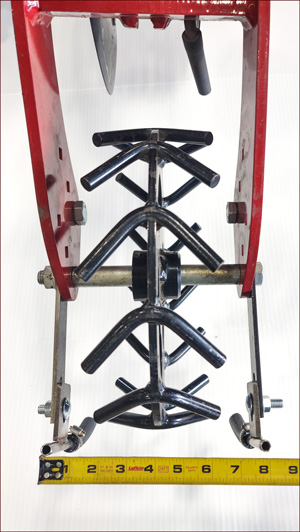

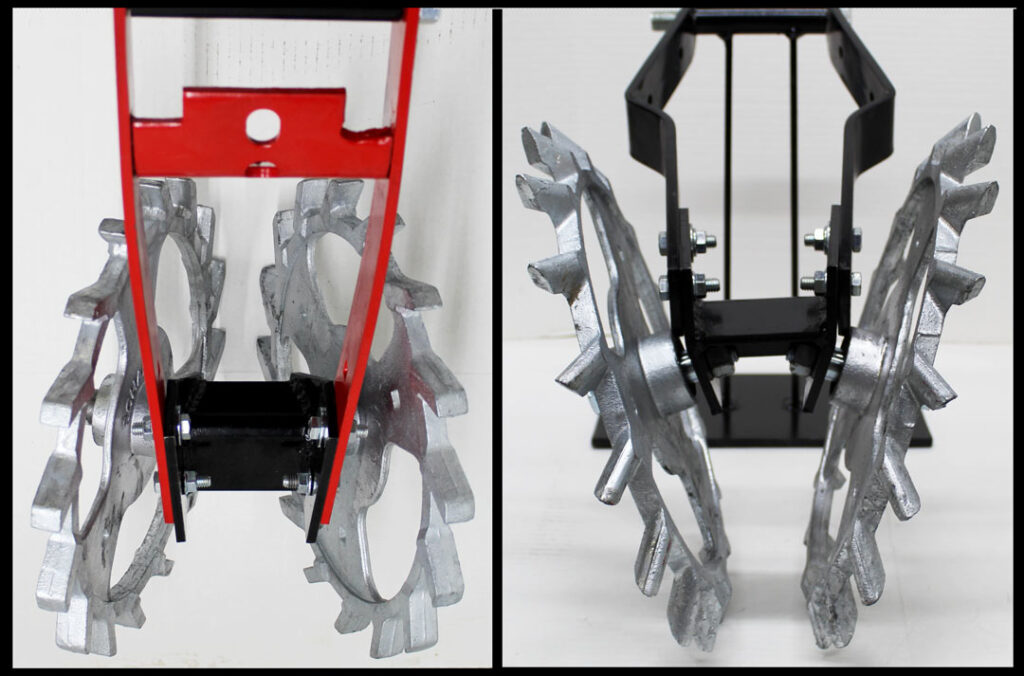

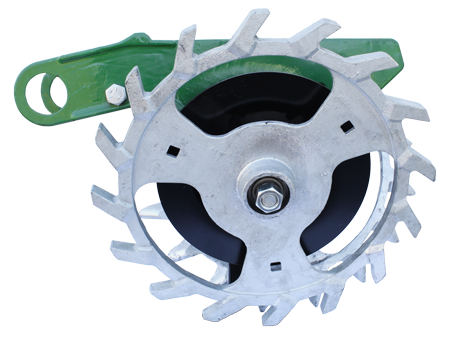

Cast Mohawk The Mohawk is a 13″ angled spiked closing wheel designed to take the place of standard, rubber closing wheels. It works in all soil types, most notably in the toughest of no-till conditions.

The Mohawk is a 13″ angled spiked closing wheel designed to take the place of standard, rubber closing wheels. It works in all soil types, most notably in the toughest of no-till conditions.

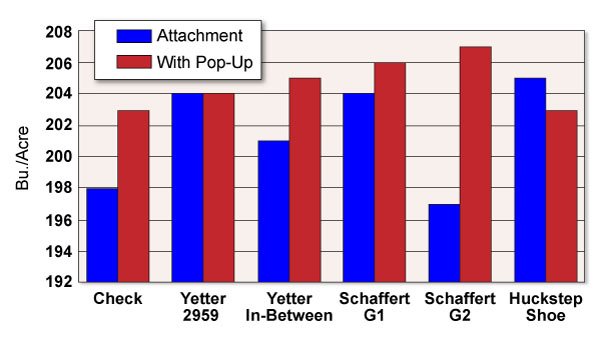

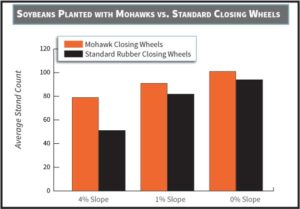

This graph shows data from a field of soybeans planted on May 29, 2013 near Ponca City, OK with Black Machine tool bar equipped with John Deere 7200 Max Emerge II row units. Some rows had standard rubber closing wheels and some had Mohawk Closing Wheels.

This graph shows data from a field of soybeans planted on May 29, 2013 near Ponca City, OK with Black Machine tool bar equipped with John Deere 7200 Max Emerge II row units. Some rows had standard rubber closing wheels and some had Mohawk Closing Wheels.